Power supply concept JB and WAB

Use of braking energy at the Jungfrau Railway and the Wengernalp Railway

The trains of Jungfraubahn AG and Wengernalpbahn AG are powered electrically, as they need to ascend from the valley up to the mountain. When descending, the trains need to be decelerated. During this process, the braking energy is transformed into electrical energy. The topographical features of the region with its substantial altitude differences and steep inclines offer significant energy optimisation potential.

Jungfrau Railway

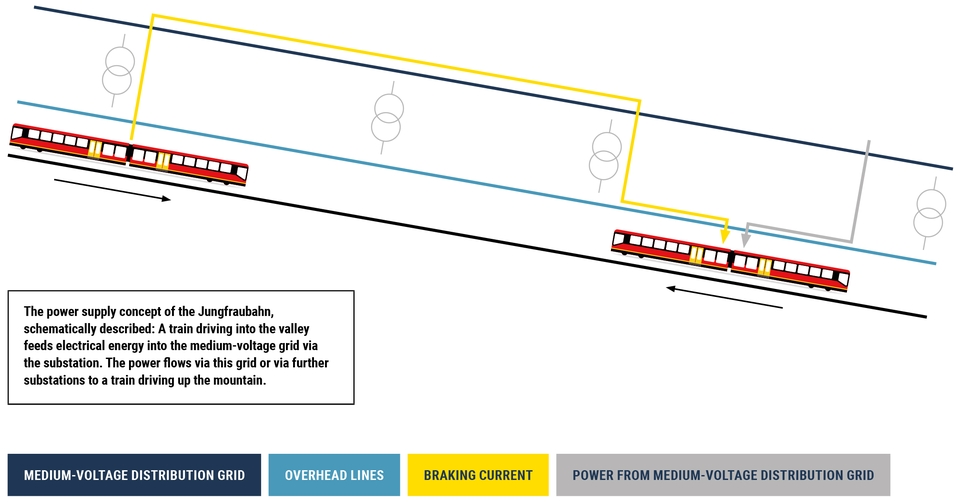

The overhead lines of the Jungfrau Railway use alternating current of 3 x 1,125 V at 50 Hz. For the feed-in from the company-owned medium-voltage grid, the route between Kleine Scheidegg and Jungfraujoch is studded with a total of 10 transformer stations, seven of which are located in the tunnel. The distances between these stations have been arranged under consideration of the incline. Thus, the ascending trains always draw power from the closest transformer station(s). Today, almost all Jungfrau Railway vehicles are able to feed in the braking current directly into the overhead lines.

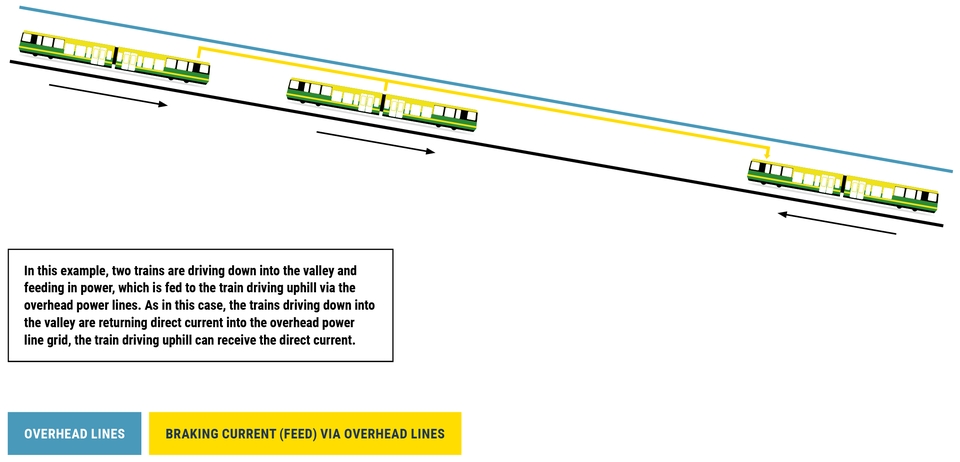

In simplified terms, a descending train supplies electrical energy to an ascending train. The power comes from the braking energy of the descending vehicle. In the best case, the other train may be operated exclusively with braking power. If this power is not sufficient, additional power can be obtained from the medium-voltage distribution grid via the said transformer stations.

In the evening, for example, when more or even all trains descend, the overhead lines are full of surplus electricity. As the Jungfrau Railway is operated with alternating current, the braking electricity can be fed into the medium-voltage distribution grid via one or several of the 10 transformer stations.

In the financial year 2020, the transport operations of Jungfrau Railways withdrew approximately 2,870,000 kWh of electricity, but also returned a remarkable 1,450,000 kWh (rounded) to the distribution grid. To demonstrate this figure: The amount of power returned roughly corresponds to the total demand of the Lauterbrunnen-Mürren Mountain Railway in 2020 or almost to that of the snow cannons of Wengernalpbahn AG.

The so-called three-phase energy supply system of the Jungfrau Railway with its two contact wires and an earthed third phase on the rail is a very rare feature.

Wengernalp Railway

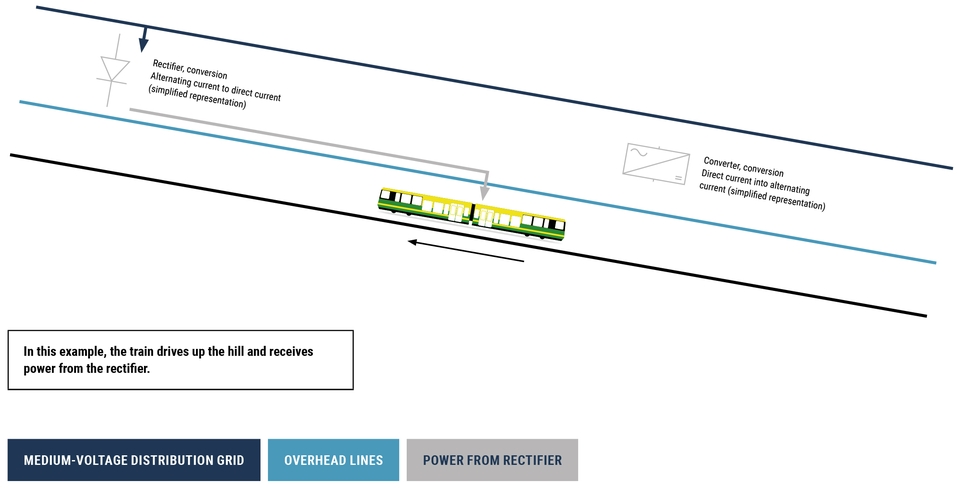

When the Wengernalp Railway was to be electrified back in the 1910s, the decision was made to implement DC overhead lines. The advantage over the system of the Jungfrau Railway was that only one wire would be needed. The medium voltage was converted from alternating current to direct current of 1,500 V by means of a rectifier. Interestingly, the people in the company still refer to the residential and technical building above Wengen as the “Rectifier”. Today, the Wengernalp Railway has a total of six modern diode rectifiers that supply the overhead line with the required 1,500 V.

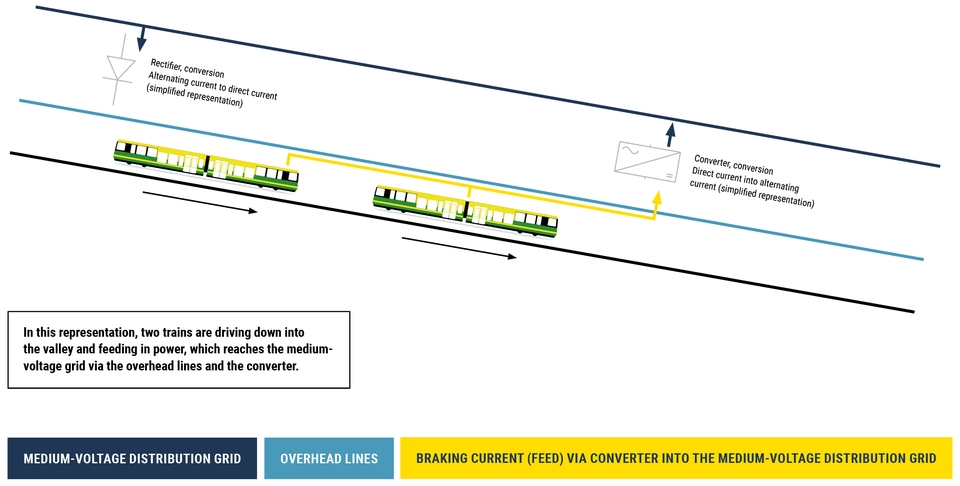

On the Wengernalp Railway, too, a large portion of the vehicle fleet is able to feed in the electrical braking energy into the overhead lines. Here too, ascending trains can often get their electricity from descending ones. As descending trains return direct current to the overhead lines, the ascending train can directly make use of the electricity. However, the diodes that convert the alternating current to direct current only enable the flow of electricity in one direction. Therefore, excess braking electricity (direct current) cannot be transmitted from the overhead lines directly to the medium-voltage distribution grid.

In the early 1990s, the decision-makers had already realised that it would also be technically feasible to feed in the braking electricity of the Wengernalp Railway into the medium-voltage distribution grid, thereby utilising valuable braking energy. Initially, the first inverter was installed in the said “Wengen Rectifier”. The inverter converts the direct current into three-phase alternating current, which is subsequently transformed to the required voltage by means of a transformer and fed into the medium-voltage distribution grid. For more than 30 years, the Wengernalp Railway has thus been able to feed in surplus braking electricity.

In 2015, the Executive Board decided to renew the two “Wengen Rectifier” and Alpiglen inverters. Such systems are very complex and need to be custom-made and designed for the individual, specific needs. The two state-of-the art inverters with IGBT technology for the Wengernalp Railway were manufactured by Simatex AG, a competent company based in Eastern Switzerland (IGBT stands for “insulated-gate bipolar transistor”). The “Wengen Rectifier" system went live in 2017, and the Alpiglen system in 2018.

Inverted rectifier system of Simatex AG at "Wengen Rectifier"

The energy fed into the medium-voltage distribution grid by the Wengernalp Railway is much less than the energy fed in by the Jungfrau Railway. This is because energy is lost both due to the conversion of direct current to alternating current and due to the greater distance of the inverters, which results in transmission losses. In 2020, the Wengernalp Railway used about 4,960,000 kWh of energy for its railway operations, while the inverters returned almost 240,000 kWh to the medium-voltage grid. This mainly takes place late in the evening and at night. The figure does not take the amount of energy that descending trains directly forward to ascending trains via the overhead lines into consideration. The amount of 240,000 kWh roughly corresponds to the annual energy demand of the Lauterbrunnen multi-storey car park. In other terms, this amount of energy would be sufficient to operate the street lights of Zweilütschinen, Gündlischwand, Lütschental and Burglauenen for 16 years.